Sound quality metrics

There are a large number of metrics, some of which are well defined and others which are not. Very few have been standardised and the usefulness of a particular metric is dependant on the nature of the sound being tested. Manufacturers who undertake sound quality testing involving the use of sound quality metrics often develop their own metrics (the definitions of which are often not generally available), as well as making use of more well known ones.

The choice of which sound quality metrics to apply is specific to individual appliance. Individual metrics do not give an indication of the sound quality as a whole and indeed for many appliances no metrics may currently exist to adequately quantify the subjective impression. Recent work [1, 2] has demonstrated that these measures are largely independent of the meaning of a sound so could never stand alone to define sound quality. This is because sound quality is usually defined using the principle of ‘how well the sound of a product matches the user’s (or bystanders) expectations’.

The Metrics

Some frequently used metrics are listed in the table below. More detailed descriptions of the metrics can be found on future pages or by clicking on the metric name.

| Index | Definitions | Applications |

| Loudness[3, 4, 5, 6, 7, 8, 9, 10] |

1. phon see BS ISO 226, where = specific loudness, | In the automobile industry: car interior noise, engine noise, exhaust noise. In domestic appliance industry, e.g. vacuum cleaners. Used to calculate sensory pleasantness. Calculation of an unbiased annoyance metric. |

| Sharpness[3, 4, 8] |

(acum) where | Automobile sounds. Domestic appliances such as vacuum cleaners and hair dryers. Used to calculate sensory pleasantness. Calculation of an unbiased annoyance metric. |

| “Boom” and low frequency SPL [11, 12] | Sound level in the 22.4 – 224 Hz frequency band. Engine harmonics below 250 Hz. | To assess vehicle interior noise. Used to calculate the composite rating of preference (CRP) for vehicles. |

| Roughness/ Raucousness/ Harshness [3, 4, 8, 13, 14, 15] |

(asper) Modulation frequency (),Perceived modulation depth () | Engine noise (e.g. cars and motorcycles). Domestic appliances such as electric razors. Used to calculate sensory pleasantness |

| Fluctuation strength[3, 4] |

(vacil) | Calculation of an unbiased annoyance metric. |

| Tones/Tonality [16] | Aures model. Concerned with the tonal prominence of a sound (are there tones present/absent). Method for calculating correction factor when the noise spectrum shows pronounced irregularities such as pure tones, Page 4 ‘BS 5727:1979 Method for describing aircraft noise heard on the ground’ Method for measuring tones in airborne noise emitted by IT and telecommunications equipment in Annex D BS EN ISO 7779:2001. | Domestic appliances such as vacuum cleaner noise. Used to calculate sensory pleasantness. |

| Overall level [3, 5 ,6 ,9 10, 15, 16] | A frequency weighting curve is applied to the decibel level which is similar to an inverted: 30 phon equal loudness contour for dB(A), 70 phon equal loudness contour for dB(B), 100 phon equal loudness contour for dB(C), 70 phon equal loudness contour but with an additional weighting to make high frequencies have a much greater level than the rest of the spectrum dB(D). | dB(A) BS 6086:1981, ‘ISO 5128- Method of measurement of noise inside motor vehicles’, ‘BS ISO 362:1998 Acoustics. Measurement of noise emitted by accelerating road vehicles. Engineering method’. dB(D) is used in the measurement of aircraft noise. |

| Time averaged level (Leq) [3, 15, 16] |

Measured in dB, p is the sound pressure. Often used with a frequency weighting curve. | Used in BS4142 (1997) |

| Sound Exposure Level ()[3, 15 ,16] |

where and Measured in dB, p is the sound pressure. | For noise events Mentioned in BS ISO 1996/1-1982(E) Description and measurement of environmental noise. Guide to quantities and procedures. |

Metrics can only replace subjective testing if they correlate well with a jury response – which is not always the case. A further list of metrics can be found by clicking here, and some examples of combination metrics can be found on the same page.

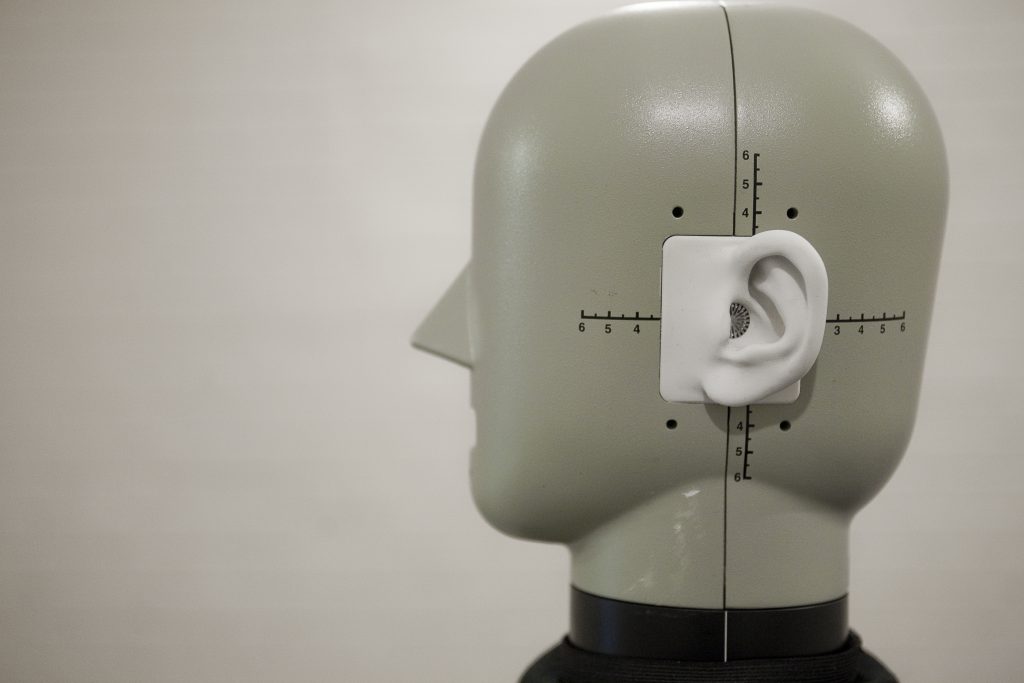

The Automobile Industry

In the automobile industry sound quality analysis is referred to as Noise Vibration Harshness (NVH) analysis. This will involve use of the above metrics. Additional analysis may include quantifying engine resonances, evaluating level differences between each ear when making binaural measurements, and separate analysis of each of the noise sources of a vehicle such as low and high frequency disc brake noise, engine noise, intake and exhaust noise, tyre/road contact noise, transmission noise and wind noise. Other terminology used in the automobile industry to describe noises includes: Squeaks, rattles, buzzes, itches and creaks which may be assessed using instationary loudness analysis [17].

References

[1] ‘Neutralizing the Meaning of Sound for Sound Quality Evaluations’, H. Fastl, Internoise (2001)

[2] ‘Predicting annoyance judgments from psychoacoustic metrics: Identifiable versus neutralized sounds’, W. Ellermeier, A. Zeitler and H. Fastl, Internoise (2004)

[3] ‘A study of standard methods for measuring the sound quality of industrial products: Final Report’, ND Porter, BF Berry, (1997)

[4] ‘Psychoacoustics and Sound Quality Metrics’ Fastl H (Sound Quality Symposium 98)

[5] ‘The problem of Predicting Noise Annoyance as a function of Distance’, K. Genuit, (Internoise 2001)

[6] ‘The use of psychoacoustic parameters combined with A-weighted SPL in noise description’ K. Genuit, (Internoise 1999)

[7] ‘Background and Practical Examples of Sound Design’ K. Genuit, Acustica Vol 83, P805 – 812, (1997)

[8] ‘21st Century Noise Control: A way to a convenient future’, K. Genuit, J. Poggenburg (Sound Quality Symposium 1998)

[9] ‘Zwicker Loudness and Metrics Calculation Only Using an Ordinary PC’, P. Ladegaard, H. Haslev, T. Schack, (Sound Quality Symposium 98)

[10] ‘A survey of Sound Quality jury evaluation correlations: Loudness vs. A-weighted Sound Level’ M. Kachur (Sound Quality Symposium 98)

[11] ‘An objective Approach to Vehicle Internal Noise Assessments’, MF Russell, Noise and the Automobile, Selected papers from Autotech ’93

[12] ‘Sound Quality Evaluation of Non-stationary Noise and Its Application to Vehicle Booming Noise’ Shin Sung-Hwan PhD thesis, (2004)

[13] P. Daniel and R. Weber, “Psychoacoustic Roughness: Implementation of an Optimized Model,” Acustica 83, 113~123 (1997).

[14] ‘Calculating Roughness Using Time-Varying Specific Loudness Spectra’ Widmann U, Fastl H (Sound Quality Symposium 98)

[15] ‘On the Perception of Periodic Sound Fluctuations (Roughness)’ E. Terhardt, Acustica Vol 30, P201-213, (1974)

[16] ‘An examination of Aures’s Model of Tonality’ A. Hastings, P. Davies (Sound Quality Symposium 2002)

[15] ‘An Introduction to the Psychology of hearing’, B. Moore, Academic Press (4th edition 2001)

[16] ‘Unit 11: Noise Concepts and Terminology’, T237:Environmental Control and Public Health Noise, OU course text, (2nd edition 2000)

[17] ‘NVH Reduction Trends’, Automotive Engineering International Online, (2000)