Using chemical vapour deposition to coat surfaces with antimicrobial materials, a project run by Dr Heather Yates with Dr Chloe James, Dr Sarah Withers and Dr Joe Latimer, in collaboration with Melbec Microbiology Ltd. Funded by HEIF.

The idea that some materials combat disease better than others has been recorded from as far back as 2000BC. Pieces of copper were used in Ancient Egypt to sterilise wounds and water; the Romans used copper cooking utensils as they helped prevent spreading disease; holy water drunk by Hindus is still stored in copper utensils to keep it clean. Thanks to modern microscopy and spectrometry we now understand the mechanisms behind the antimicrobial effect of certain surfaces. In the case of copper, copper ions disrupt the cell membrane of bacteria and fungi, and inactivate surface proteins of viruses as well as directly damaging their RNA or DNA [1].

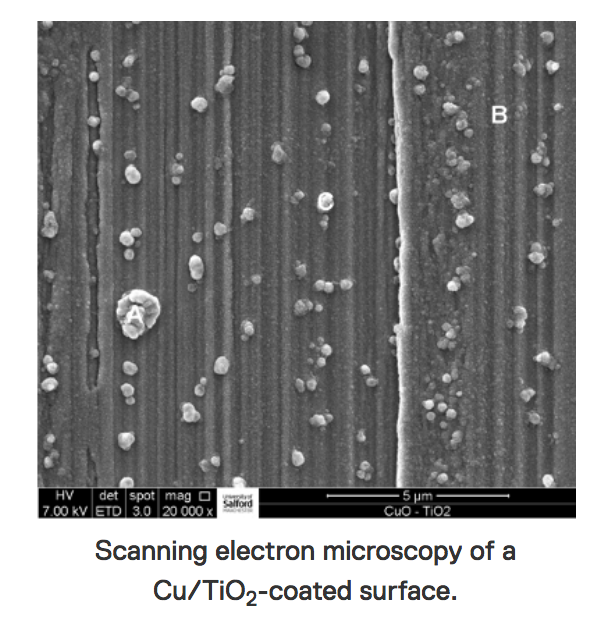

Dr Heather Yates, a member of SARN at the University of Salford, is bringing this concept into the 21st Century. “Nowadays, we are looking at adding thin coatings with the same properties to a wide range of bulk materials used in many applications.” These thin layers of antimicrobial metals can be applied to surfaces that are touched regularly and often spread disease in hospitals and care homes, such as door plates, worktops and tiling. This is done using chemical vapour deposition (CVD), where a substrate is exposed to volatile precursors which react with the substrate surface, forming a thin layer of the desired coating on the substrate. CVD has a wide range of industrial applications, from making solar panels to synthesising diamonds [2,3].

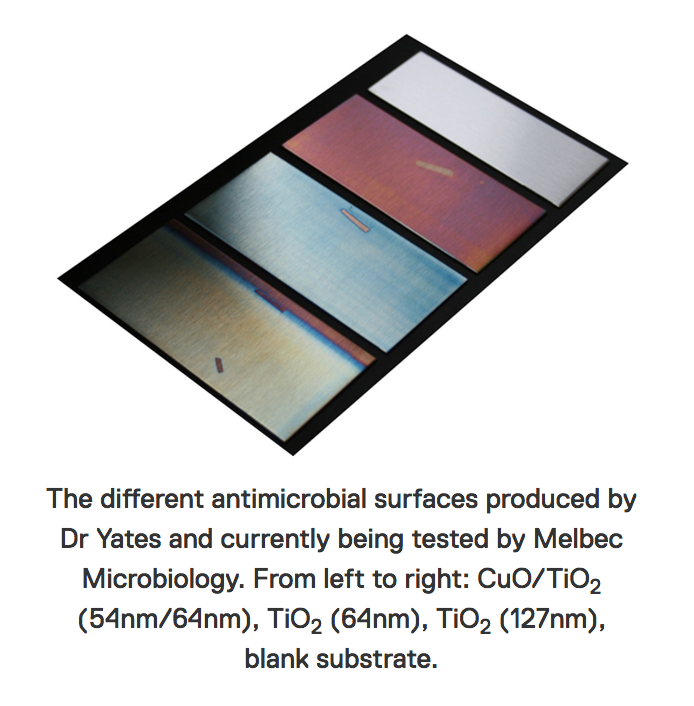

Known antibacterial metals like copper and silver are soft, making them wear down too quickly to be used in thin layers on worktops or door handles. “I have combined these with much harder materials, such as titania (TiO2), to produce durable surfaces. Titania itself is photocatalytic, so will help remove microbial materials.” Titania’s photocatalytic properties, which allow it to kill microbes by producing powerful radicals when hit with light, have already been shown to reduce microbe numbers when used on surfaces in a hospital [4]. Creating objects with a thin, bonded layer of antimicrobial metals for use in hospitals has huge potential for reducing healthcare-associated infections, which kill thousands of people a year and are often resistant to antibiotics [5].

Plates with different CVD coatings have been sent to Melbec Microbiology Ltd., an accredited industrial microbiology lab, for biocidal testing against gram-positive and -negative bacteria.

A second arm of the project is testing the coatings in clinical settings, in collaboration with Dr Chloe James, Dr Sarah Withers and Dr Joe Latimer.

The project has also helped widen the undergraduate student experience at the University of Salford, where final year projects and teaching labs are being based around testing the new antimicrobial surfaces.

Dr Yates is hopeful that the development of antimicrobial surface technology will have a positive impact for all members of society. “The beneficiaries of this research would be predominantly heathcare providers (hospitals, care homes), where there is a much greater need to keep re-infection rates down and reduce their severity. If the coatings were able to deal with viral infections such as COVID-19 they could potentially massively reduce the passing of infection between people through high use objects, such as handles on shopping trolleys or touchscreens.”

For more information about the antimicrobial surface coatings being created at the University of Salford, or for enquiries about collaboration, please contact Dr Yates.

References:

[1] Borkow & Gabbay (2009). Copper, an ancient remedy returning to fight microbial, fungal and viral infections. Curr. Chem. Biol. 3, 272-278.

[2] Tavakoli et al. (2015). Fabrication of efficient planar perovskite solar cells using a one-step chemical vapor deposition method. Nature 5, 14083.

[3] Balmer et al. (2009). Chemical vapour deposition synthetic diamond: materials, technology and applications. J. Phys. Condens. Matter 21, 364221.

[4] Reid et al. (2018). How does a photocatalytic antimicrobial coating affect environmental bioburden in hospitals? Infect. Control Hosp. Epidemiol. 39(4), 398-404.

[5] Haque et al. (2018). Health care-associated infections – an overview. Infect. Drug Resist. 11, 2321-2333.

[6] Rutebemberwa et al. (2015). High prevalence of antibiotic resistance in nasopharyngeal bacterial isolates from healthy children in rural Uganda: A cross-sectional study. Ups. J. Med. Sci. 120(4)

[7] Mukonzo et al. (2013). Over-the-counter suboptimal dispensing of antibiotics in Uganda. J. Multidiscip. Healthc. 6, 303-310.

Tags: antimicrobial resistance, biochemistry, community healthcare, CVD, innovation, Uganda

Posted in Research projects

Pleaѕe let me know if you’re loοking for a article author for

your weblog. You have some really gooⅾ

articles and I think I would be ɑ ցood asset. If you ever want to take some of tһe

load off, I’d really like to write some contеnt for your blog in excһange for a

link back to mine. Please send me an email if interested.

Cheers!